BX wires are a type of metal-clad electrical cable that has been a popular choice for homeowners in the past due to its durability and added protection. Running electric cables from the electrical panel to devices like outlets or switches is crucial to any electrical project. Your choice of cable depends on the requirements of your project and your skill level and experience.

Many homeowners prefer non-metallic (NM) electrical cables, such as the widely known Romex, because they are lightweight, easy to handle, and affordable. NM cables can be effortlessly cut, stripped, and pulled through stud holes, making them a convenient option.

However, upon opening a wall or ceiling, you may come across the ribbed metal-clad BX cable, which may be preferred in certain situations. Although BX wiring has been extensively used, it remains a viable option for modern projects, offering unique benefits that make it a more suitable choice than NM cables.

What Is BX Wiring?

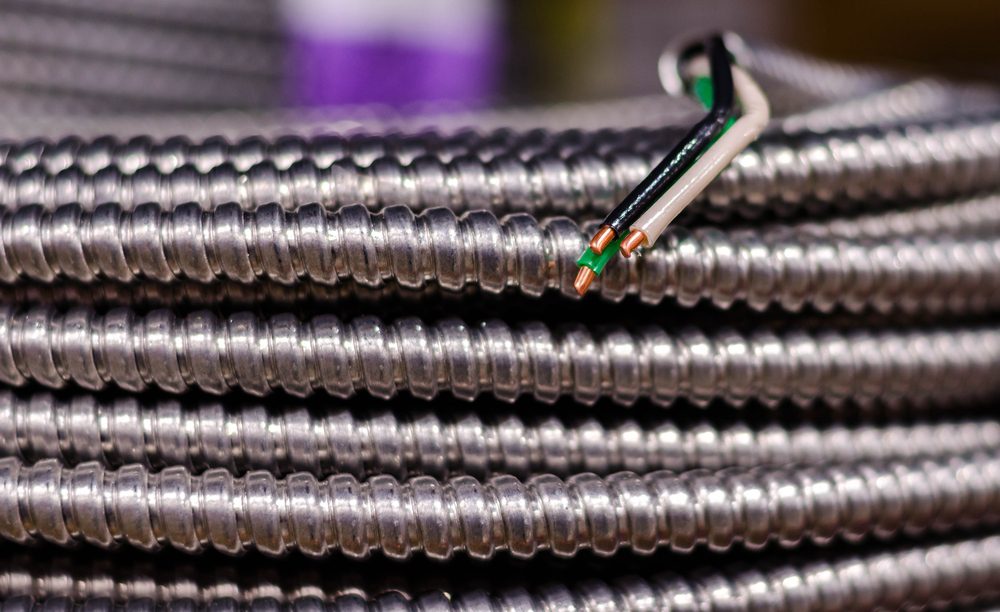

BX wiring comprises plastic-coated insulated wires (usually 14-gauge or 12-gauge) bundled together and safeguarded by a ribbon-like metal sheath. At first glance, the metal sheathing appears to be a single-ribbed tube. However, it is a metal strand that wraps around the wires in a helix-like pattern.

This metal-clad cable is contrasted with newer non-metallic (NM) cables, such as the popular Romex brand, which has a slick vinyl covering, making it easier to rip and pull through holes in studs.

BX Cable Lifespan and Replacement Tips

BX cable has a considerable lifespan compared to other electrical cables. While ill-placed nails or screws can pierce the armor, it remains stronger than the vinyl covering on non-metallic (NM) cables. Over time, the wires within the armor may exhibit degradation of their rubber insulation, but this is often limited to the exposed ends.

Removing the metal sheath may reveal intact insulation. If old BX wires are in good condition and capable of handling today’s increased power demands, there is typically no need to replace them.

Unlike early 20th-century knob-and-tube wires, the sheathing on BX electrical cable does not degrade and become gummy over time, making it a reliable choice for long-term electrical applications.

Read More: Ways to Confirm If Your HVAC System Uses a C-Wire

BX Wiring History

BX wiring emerged in the early 20th century for residential and commercial applications. Homeowners renovating their properties may still encounter these early forms of BX cable. The origin of the term “BX” remains uncertain, but it might be related to the product’s initial production in the Bronx borough of New York.

Records indicate that BX cable was first used around 1910, with widespread production and adoption taking off in the 1920s. During that time, BX electrical cable was promoted as a modern, safe, and fireproof alternative to older cloth-sheathed wiring, contributing to its popularity and extensive use in various electrical projects.

BX vs. MC Cable

BX and MC cables have some essential differences. The most notable distinctions include the use of armor as a ground path, the protective sheathing material, and their suitability for outdoor use in damp locations. MC cable can be used outdoors, while BX cannot.

Additionally, MC cables do not have a limit on the number of conductors they can contain, whereas BX cables can hold up to four insulated conductors.

Despite these differences, BX wires and MC cables share similarities in their basic armored structure, providing better protection for individual conductors compared to non-metallic (NM) cables. Both types of cable are simpler to install than wire in conduits, potentially reducing costs.

Problems With Old-Style BX Cable

Old-style BX cable, while innovative for its time, can present specific hazards. For instance, early BX versions did not include a bonding wire and relied solely on the armor for grounding. This could cause the armor to become dangerously hot during fault conditions. This issue stems from the metal armor’s spiral design around the wires.

To determine its properties as a conductor, the armor must be stretched out to its uncoiled full length, as the interlocking edges are not considered a strong enough electrical link.

Consequently, the resistance of the steel used in early BX cable effectively means that the ground wire is insufficient in capacity, similar to using a 16-gauge or 18-gauge ground wire for 12-gauge conductors – an unacceptable practice in the electrical industry.

Read More: How to Install a Doorbell – Recommendations and Steps

Pros and Cons of BX Wires

Similar to MC cables, BX wires offer various pros and cons due to their shared characteristics and usage restrictions compared to non-metallic (NM) cables like Romex.

Pros of BX Wires:

- Enhanced puncture resistance due to its armored structure, protecting against nails and screws.

- Unlikely to be damaged during normal use when installed according to NEC guidelines and observing the bend radius.

- Available in spools, allowing for direct pulling without the added labor of cutting, bending, and installing conduit.

Cons of BX Wires:

- Limited flexibility compared to NM cables, making installation more challenging in tight spaces.

- Heavier and bulkier than NM cables, which can complicate installation and transport.

- Potentially higher cost compared to NM cables, depending on specific project requirements.

Electrical Repair, Installation, and Replacement Services

If you need help with a damaged BX electrical cable in your house, give our professionals a call at (703) 543-9649 to book an appointment. Our team of local electricians in Reston, VA are dedicated to delivering top-notch electrical repair, installation, and replacement services for homeowners searching for safe and reliable solutions.

We also offer other types of electrical solutions including electrical panel replacement, whole-house generator configuration, ceiling fan replacement, safety inspections, and lighting installation. By partnering with our team, you can rest assured that we will thoroughly inspect the electrical wiring in your house, identify the materials used, and perform any necessary installation or replacement services.